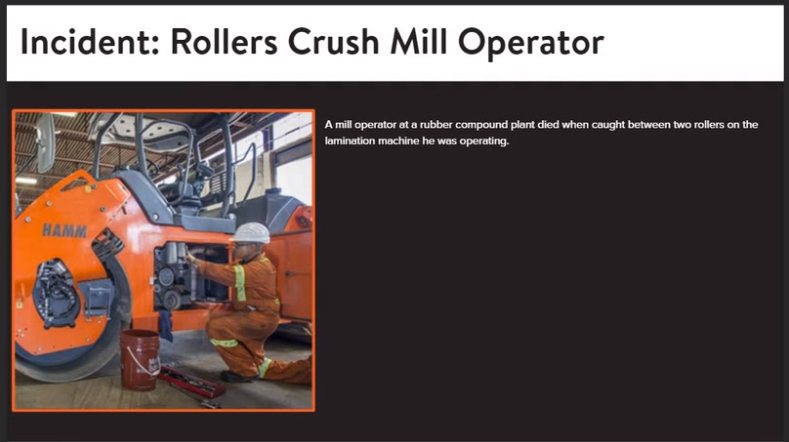

Workers who operate and maintain machinery suffer approximately 18,000 injuries and over 800 deaths per year. Machine safeguards are your first line of defense against injuries caused by moving machines.

Machine Guarding

$9.99

Description

Workers who operate and maintain machinery suffer approximately 18,000 injuries and over 800 deaths per year.

…and machine safeguards are your first line of defense against injuries caused by moving machines.

So what are machine guards?

Machine guarding is a precautionary safety feature on manufacturing or other engineering equipment. Specifically, it is a shield or device covering hazardous areas of a machine to prevent contact with body parts or to control hazards like chips and noise from exiting the machine.

In order for machine guards to be effective, they must:

- Prevent contact

- Be secured in place or otherwise be tamper proof

- Create no new hazard

- Allow for lubrication with the guard still in place

- Not interfere with the machine operation

Here are the four most common types of machine guards:

- Fixed guards: Fixed guards are a permanent part of the machine

- Interlocking guards: Interlocking guards can be opened or removed. When they are, the power automatically shuts off, the moving parts of the machine are stopped, and the machine cannot be started until the guard is back in place.

- Adjustable guards: Allow flexibility in accommodating various sizes of material while still protecting the point of operation. These guards must be adjusted manually.

- Self-adjusting guards: Self-adjusting guards are barriers determined by the movement of the material. As the operator moves the material into the danger area, the guard is pushed away, providing an opening which is only large enough to admit the material.

Modern machines save workers time and are essential for some careers in today’s workplace. Take the precautionary steps to be safe and keep workers out of harm’s way.

Until next time, stay positive and stay safe.

Why SafetyNow?

Not all training is equal. With SafetyNow, learners and leaders will notice the difference in value:

- Quality: Professionally-researched and designed using the latest mobile and responsive technologies

- Convenience: Works instantly on any device, desktop or mobile

- Time savings: What learners need to know, not extra fluff or legalese

- Reporting: Consistent, instant compliance records available anytime

- Support: Customer and learner support included at no charge

- Understanding the hazards of working with mechanical equipment, including where those hazards occur and the motions and actions that cause the hazards

- Recognizing the purpose of machine safeguarding, safeguarding device requirements, factors that influence safeguarding methods, and the safeguarding methods used to protect you from mechanical hazards

- Acknowledging your responsibilities to utilize machine safeguards properly

- Any Learning Management System (LMS) Use with any SCORM, AICC, xAPI, TinCan, HTML5, or other LMS (learning management system).

- Any Device Desktop, laptop, tablet, or mobile phone – it simply works, everywhere.

- Engaging Professionally-developed, including an on-screen host and modern, easy-to-understand text, media, and voiceovers.

- Unlimited Attempts Each module can be taken as many times as required to get a passing grade. Unlike our competitor’s courses, if you get an answer wrong, you are redirected to the exact eLearning segment you struggled with… you don’t need to go through the entire module again, just the one part you need a refresher on.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.