Prior to any excavation, trenching, or shoring activities, you must take specific steps to setup the site to avoid the accidental disruption of utilities, and assure the stability of adjacent structures—you need to engineer some controls and take precautionary measures.

Excavation and Trenching

Original price was: $11.99.$9.99Current price is: $9.99.

Description

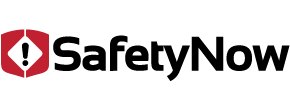

Of all annual occupational deaths in the nation, deaths caused by excavation cave-ins account for nearly 1%.

Prior to any excavation, trenching, or shoring activities, you must take specific steps to setup the site to avoid the accidental disruption of utilities, and assure the stability of adjacent structures—you need to engineer some controls and take precautionary measures. You may need to ensure your safe access into and out of the excavation and avoid the hazards of contaminated atmospheres, falling materials, and the collapse of excavation walls, through the use of protective systems. Numerous things can go wrong with these scenarios, so awareness and preparedness are critical priorities for protecting everyone.

Before opening an excavation, you need to take the proper steps to protect yourself, other employees, and any underground equipment. Firstly, your employer must determine the location of utility installations, such as sewer, telephone, fuel, electric, and water lines, or any other underground installations. Majority of areas have a “call before you dig” local resource for locating problem dig areas, so that’s a good number to have and share with your team; if excavation work is a daily part of your business, that number should be memorized.

For everyone’s safety, the excavation needs to have a proper method of access and escape. Varying with the size of the excavation, this could mean structural ramps, stairs, or ladders, to be used only by authorized employees; it is fundamental that these areas are clearly marked to keep non-participants, like other contractors on a job site, out and away for excavation operations.

Below are basic safety precautions for you to implement while performing excavation work:

- Excavations less than four feet in depth do not require a stairway, anchored ladder, or ramp. Excavations at or over four feet in depth require one of these structures, or other safe means of access and egress. This way, employees do not have to travel more than 25 feet to get out of the excavation from any point within the excavation.

- As well, walkways need to be provided where employees or equipment are permitted to cross over excavations. Guardrails that satisfy OSHA requirements must be provided where walkways are 6 feet or more above lower levels. Be cognizant of your surroundings. Do not go beneath loads handled by lifting or digging equipment.

- Avoid vehicles that being loaded or unloaded, to avoid being struck by any spillage or falling materials. When the vehicles are equipped to provide adequate protection for the operator, they can stay in vehicle cabs that are being loaded or unloaded.

- Warning devices must be in place whenever mobile equipment is operated next to or near the edge of an excavation and the operator does not have a clear view of the edge of the excavation. Examples of warning systems include barricades and stop logs, and hand or mechanical signals. Whenever possible, all grade should be sloped away from the excavation.

- Always have emergency rescue equipment available. Breathing apparatuses should always be on site, in addition to a safety harness and lifeline, both of which are required in confined spaces, and a basket stretcher.

- Use diversion ditches, dikes, or other suitable methods to prevent surface water from entering the excavation and to provide adequate drainage of the area next to the excavation.

- Anywhere that the stability of nearby buildings, walls, or other structures is endangered by excavation operations, support systems are required. Examples include shoring, bracing, and underpinning, to ensure stability and protect employees.

- During an excavation, you need to have protection from cave-ins. A protective systems purposed for this could include sloping and bench systems, and support systems, such as aluminum hydraulic shoring. Also, these systems need to have the capacity to resist any reasonably expected load that could be applied to the system.

Why SafetyNow?

Not all training is equal. With SafetyNow, learners and leaders will notice the difference in value:

- Quality: Professionally-researched and designed using the latest mobile and responsive technologies

- Convenience: Works instantly on any device, desktop or mobile

- Time savings: What learners need to know, not extra fluff or legalese

- Reporting: Consistent, instant compliance records available anytime

- Support: Customer and learner support included at no charge

- Recognizing safety requirements when setting up an excavation site.

- Evaluating hazards in and around an excavation, trenching, and shoring site.

- Developing precautions, protective measures, and the types of support systems used at an excavation site.

- Acknowledging cave-in protection requirements and learning proper procedures to keep employees safe on an excavation.

- Any Learning Management System (LMS) Use with any SCORM, AICC, xAPI, TinCan, HTML5, or other LMS (learning management system).

- Any Device Desktop, laptop, tablet, or mobile phone – it simply works, everywhere.

- Engaging Professionally-developed, including an on-screen host and modern, easy-to-understand text, media, and voiceovers.

- Unlimited Attempts Each module can be taken as many times as required to get a passing grade. Unlike our competitor’s courses, if you get an answer wrong, you are redirected to the exact eLearning segment you struggled with… you don’t need to go through the entire module again, just the one part you need a refresher on.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.