-

Learning Objectives

- Describe the basic principle of hydraulics

- Explain the effect air can have on hydraulic systems

- Identify five components common to most hydraulic systems

- Describe two key considerations that must be taken into account when selecting a hydraulic pump

- Identify the two most common types of hydraulic circuits

-

In this course you’ll learn about the chemistry of Hydrogen Sulfide and how it is formed, the properties and characteristics of the gas, where Hydrogen Sulfide is likely to be located in your workplace, the potential health hazards of short term and long term H2S exposure, how to work safely with Hydrogen Sulfide and emergency response steps to take should you or a co-worker be exposed to this gas.

In this course you’ll learn about the chemistry of Hydrogen Sulfide and how it is formed, the properties and characteristics of the gas, where Hydrogen Sulfide is likely to be located in your workplace, the potential health hazards of short term and long term H2S exposure, how to work safely with Hydrogen Sulfide and emergency response steps to take should you or a co-worker be exposed to this gas. -

All employers covered by the Act are regulated by Part 1904 regulations. However, businesses with 10 or fewer employees and businesses with certain industry classifications are partially exempt from keeping OSHA injury and illness records, unless OSHA or the Bureau of Labor Statistics notifies them in writing that they must do so. All employers covered by OSHA—no matter the number of employees or industry classification—must report to OSHA any workplace incident that results in a fatality or the hospitalization of three or more employees.

All employers covered by the Act are regulated by Part 1904 regulations. However, businesses with 10 or fewer employees and businesses with certain industry classifications are partially exempt from keeping OSHA injury and illness records, unless OSHA or the Bureau of Labor Statistics notifies them in writing that they must do so. All employers covered by OSHA—no matter the number of employees or industry classification—must report to OSHA any workplace incident that results in a fatality or the hospitalization of three or more employees. -

Recent statistics from the Congressional Accountability Office of Compliance indicate that employee falls are private industry’s third leading cause of workplace fatalities. Around 600 workers die from a fatal slip, trip, or fall, each year. This overview of slips, trips, and falls helps reinforce good behaviors for workers on how and where to avoid areas where these hazards can reside.

Recent statistics from the Congressional Accountability Office of Compliance indicate that employee falls are private industry’s third leading cause of workplace fatalities. Around 600 workers die from a fatal slip, trip, or fall, each year. This overview of slips, trips, and falls helps reinforce good behaviors for workers on how and where to avoid areas where these hazards can reside. -

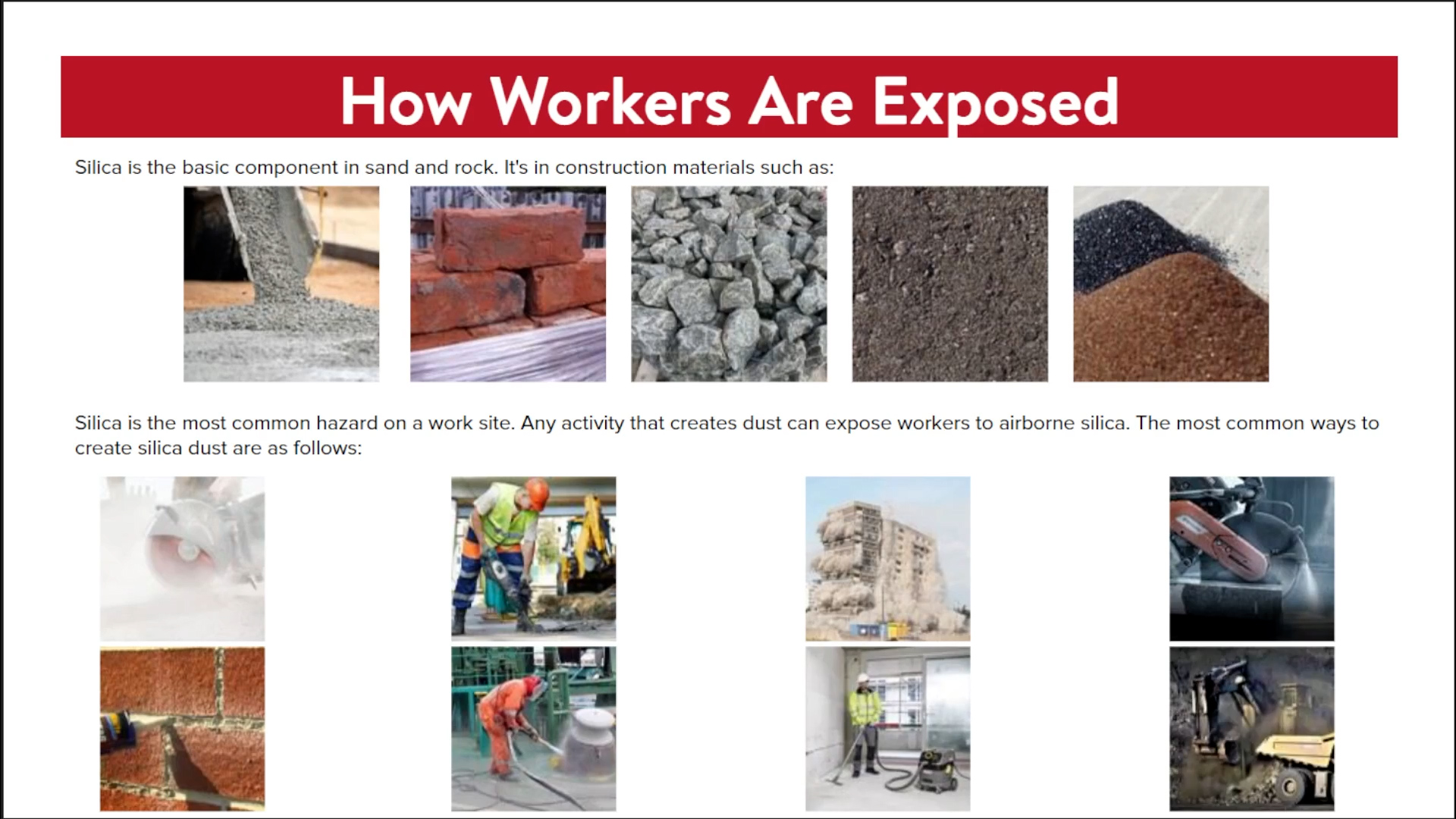

This lesson is designed as an intro/refresher to our Silica Hazards course in order to improve the safety of workers in environments where silica exposure hazards exist by increasing employee awareness of this hazard and by demonstrating how the hazard can be recognized and addressed in the workplace.

This lesson is designed as an intro/refresher to our Silica Hazards course in order to improve the safety of workers in environments where silica exposure hazards exist by increasing employee awareness of this hazard and by demonstrating how the hazard can be recognized and addressed in the workplace. -

The goal of this lesson is to teach workers the purpose of respirators and the preparations, maintenance and storage requirements. Workers will also learn when it is permissible to leave a respirator use area, the warning signs that a respirator is not functioning properly, and how respirator emergencies and malfunctions should be handled.

The goal of this lesson is to teach workers the purpose of respirators and the preparations, maintenance and storage requirements. Workers will also learn when it is permissible to leave a respirator use area, the warning signs that a respirator is not functioning properly, and how respirator emergencies and malfunctions should be handled. -

The goal of the lesson is make employees aware of the primary objective of process safety management: to prevent unwanted releases of highly hazardous chemicals into locations that expose employees and others to serious hazards, and to provide an overview of the standards and best practices necessary to achieve that objective.

The goal of the lesson is make employees aware of the primary objective of process safety management: to prevent unwanted releases of highly hazardous chemicals into locations that expose employees and others to serious hazards, and to provide an overview of the standards and best practices necessary to achieve that objective. -

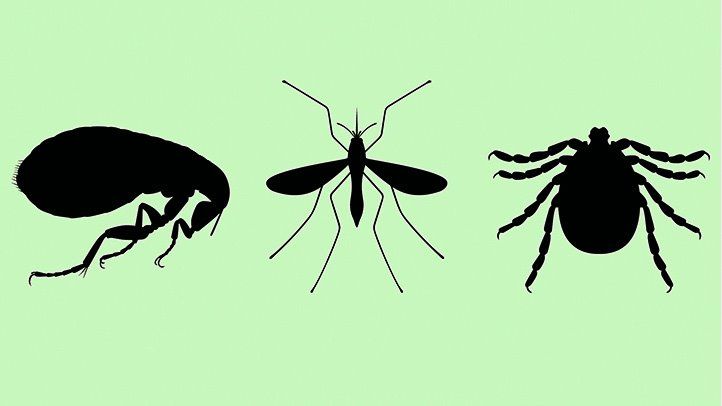

In this lesson, you will learn about the most-common vector-borne diseases and how you can avoid exposure and infection. You will learn general treatment guidelines; however, any treatment-related information provided in this lesson does not constitute medical advice and is not a substitute for evaluation by a qualified healthcare professional.

In this lesson, you will learn about the most-common vector-borne diseases and how you can avoid exposure and infection. You will learn general treatment guidelines; however, any treatment-related information provided in this lesson does not constitute medical advice and is not a substitute for evaluation by a qualified healthcare professional. -

This Lock and Tag lesson creates awareness about the purpose of lock and tag procedures and employee roles and responsibilities related to lock and tag requirements. The lesson provides an overview of the hazards of uncontrolled energy sources and employer responsibilities and requirements for lock and tag. It also briefly outlines steps to protect workers.

This Lock and Tag lesson creates awareness about the purpose of lock and tag procedures and employee roles and responsibilities related to lock and tag requirements. The lesson provides an overview of the hazards of uncontrolled energy sources and employer responsibilities and requirements for lock and tag. It also briefly outlines steps to protect workers. -

As simple as using a ladder seems to be, the injury statistics indicate that it is one of the most abused tools we have. Accidents, particularly in the domestic setting, are frequently caused by overreaching or overextending from ladders to complete certain tasks, rather than doing the safe thing—climbing down and moving to a better access point. OSHA studies have shown that 100% of ladder related accidents could have been prevented using proper safety. The goal of this lesson is to provide awareness-level instruction on ladder hazards, safe use requirements, and best practices for all employees.

As simple as using a ladder seems to be, the injury statistics indicate that it is one of the most abused tools we have. Accidents, particularly in the domestic setting, are frequently caused by overreaching or overextending from ladders to complete certain tasks, rather than doing the safe thing—climbing down and moving to a better access point. OSHA studies have shown that 100% of ladder related accidents could have been prevented using proper safety. The goal of this lesson is to provide awareness-level instruction on ladder hazards, safe use requirements, and best practices for all employees. -

According to the National Federation of Independent Businesses defines ideal safety accountability as the following:

According to the National Federation of Independent Businesses defines ideal safety accountability as the following:- Ideal accountability

- Companies that strive for optimal safety performance display the highest level of organizational safety accountability

-

Common hazards associated with pallet jack operation include falling objects (struck by hazards). Loads can fall, and operators can too. If you move a loaded pallet jack too quickly, over uneven floors, or on inclines, the load may topple. You could be injured if the load falls, and the load and/or the workplace may be damaged. Straining to move a stuck pallet jack or failing to maintain control on an incline can cause the operator to slip and fall. This lesson focuses on the safe operation of both manual and powered hydraulic pallet jacks.

Common hazards associated with pallet jack operation include falling objects (struck by hazards). Loads can fall, and operators can too. If you move a loaded pallet jack too quickly, over uneven floors, or on inclines, the load may topple. You could be injured if the load falls, and the load and/or the workplace may be damaged. Straining to move a stuck pallet jack or failing to maintain control on an incline can cause the operator to slip and fall. This lesson focuses on the safe operation of both manual and powered hydraulic pallet jacks. -

Workers loading and unloading materials should be instructed in safe procedures appropriate to the material they handle. Truck or rail tank car loading or the unloading of flammable/combustible liquids is one of the most hazardous operations likely to be undertaken at any manufacturing or storage facility. Workers engaged in the loading or unloading of suspension-type highway trailers may be at an increased risk of injury due to the inability of damaged trailers to support the weight of the powered industrial truck used to load or unload the trailer. The goal of this lesson is create awareness of these hazards and to provide knowledge to the learner on how to avoid accidents and/or injury.

Workers loading and unloading materials should be instructed in safe procedures appropriate to the material they handle. Truck or rail tank car loading or the unloading of flammable/combustible liquids is one of the most hazardous operations likely to be undertaken at any manufacturing or storage facility. Workers engaged in the loading or unloading of suspension-type highway trailers may be at an increased risk of injury due to the inability of damaged trailers to support the weight of the powered industrial truck used to load or unload the trailer. The goal of this lesson is create awareness of these hazards and to provide knowledge to the learner on how to avoid accidents and/or injury. -

Hydrogen sulfide is a chemical compound with the formula H2S. It is an extremely hazardous gas whose marker is the smell of rotten eggs. It is colorless and very dangerous when high concentrations are inhaled. Hydrogen sulfide is highly flammable and explodes easily near lit matches, cigarettes, and other sources of spark or heat. Although only a little irritating at lower concentrations, hydrogen sulfide exposure can result in death. The most likely and dangerous exposure pathway is through inhalation of hydrogen sulfide gas, however, there are some instances where contact is made with the skin. Contact with the skin can result in frostbite or burns.

Hydrogen sulfide is a chemical compound with the formula H2S. It is an extremely hazardous gas whose marker is the smell of rotten eggs. It is colorless and very dangerous when high concentrations are inhaled. Hydrogen sulfide is highly flammable and explodes easily near lit matches, cigarettes, and other sources of spark or heat. Although only a little irritating at lower concentrations, hydrogen sulfide exposure can result in death. The most likely and dangerous exposure pathway is through inhalation of hydrogen sulfide gas, however, there are some instances where contact is made with the skin. Contact with the skin can result in frostbite or burns. -

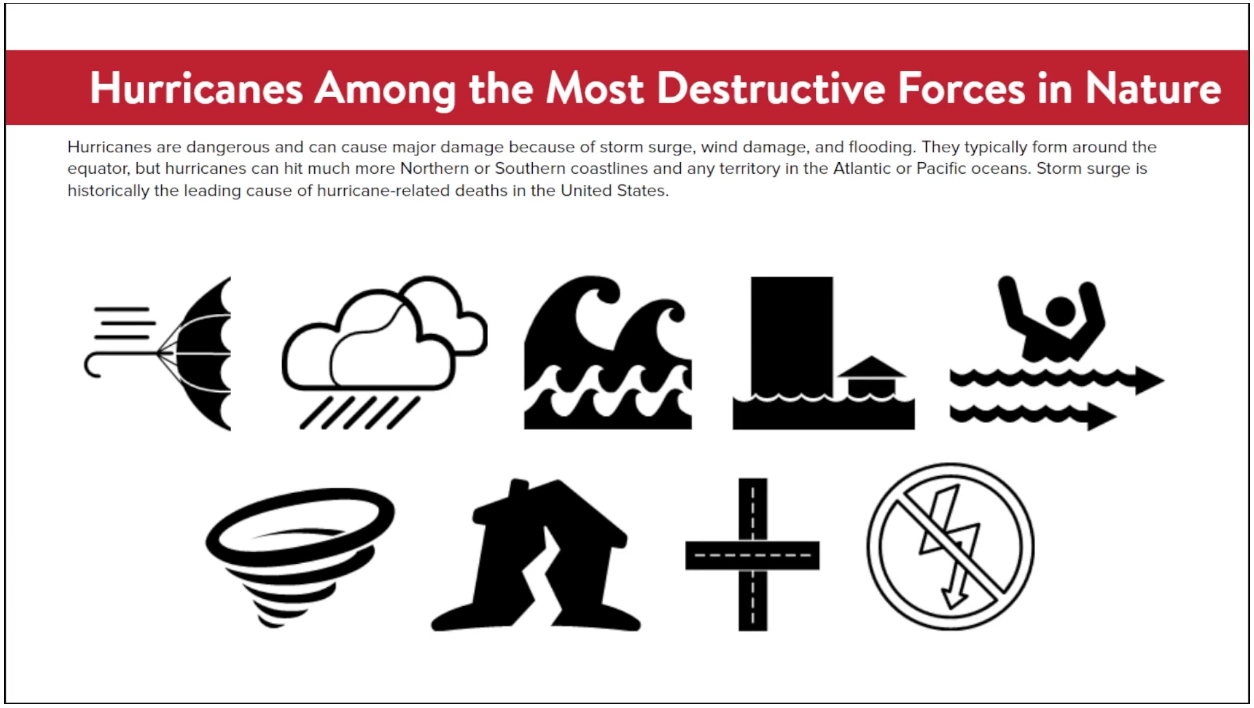

Hurricanes are dangerous and can cause major damage because of storm surge, wind damage, and flooding. They typically form around the equator, but hurricanes can hit much more Northern or Southern coastlines and any territory in the Atlantic or Pacific oceans. This course will help you understand how to prepare for a hurricane.

Hurricanes are dangerous and can cause major damage because of storm surge, wind damage, and flooding. They typically form around the equator, but hurricanes can hit much more Northern or Southern coastlines and any territory in the Atlantic or Pacific oceans. This course will help you understand how to prepare for a hurricane. -

This lesson will help you recognize the impact of noise on your hearing, the warning signs of hearing loss, and the noise exposure limits that necessitate hearing protection. This lesson will also introduce you to the types of hearing protectors, including their benefits and proper use, and address your responsibilities in supporting your employer’s hearing conservation program.

This lesson will help you recognize the impact of noise on your hearing, the warning signs of hearing loss, and the noise exposure limits that necessitate hearing protection. This lesson will also introduce you to the types of hearing protectors, including their benefits and proper use, and address your responsibilities in supporting your employer’s hearing conservation program. -

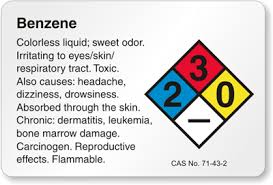

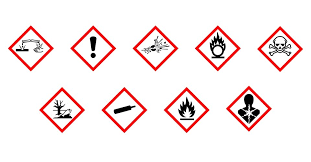

The goal of this lesson is for employees to recognize and understand how to identify chemical hazards using the GHS international classification of chemical hazards, label elements, and Safety Data Sheets. This lesson does not address the use of labels, markings or other communication methods that are employer or facility-specific and not within the scope of this lesson.

The goal of this lesson is for employees to recognize and understand how to identify chemical hazards using the GHS international classification of chemical hazards, label elements, and Safety Data Sheets. This lesson does not address the use of labels, markings or other communication methods that are employer or facility-specific and not within the scope of this lesson.