-

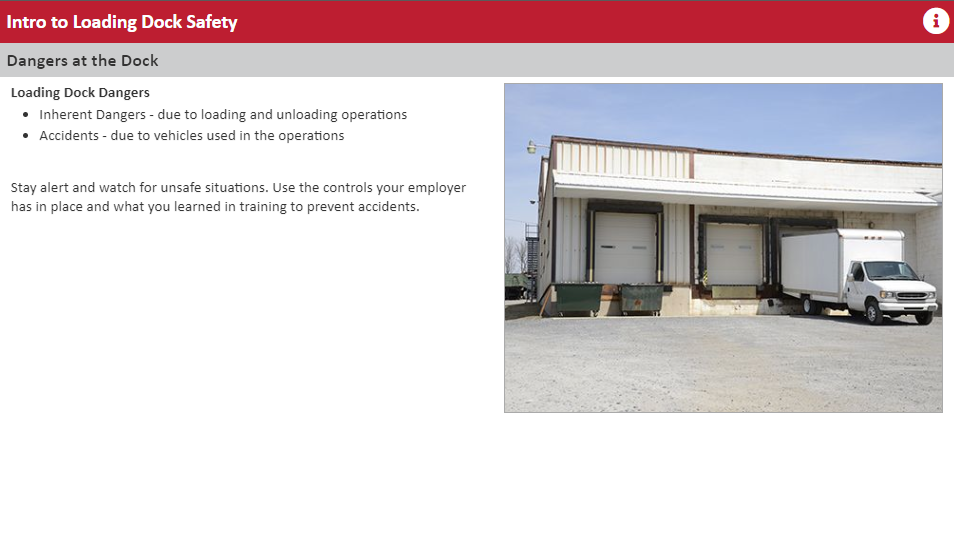

Workers loading and unloading materials should be instructed in safe procedures appropriate to the material they handle. Truck or rail tank car loading or the unloading of flammable/combustible liquids is one of the most hazardous operations likely to be undertaken at any manufacturing or storage facility. Workers engaged in the loading or unloading of suspension-type highway trailers may be at an increased risk of injury due to the inability of damaged trailers to support the weight of the powered industrial truck used to load or unload the trailer. The goal of this lesson is create awareness of these hazards and to provide knowledge to the learner on how to avoid accidents and/or injury.

Workers loading and unloading materials should be instructed in safe procedures appropriate to the material they handle. Truck or rail tank car loading or the unloading of flammable/combustible liquids is one of the most hazardous operations likely to be undertaken at any manufacturing or storage facility. Workers engaged in the loading or unloading of suspension-type highway trailers may be at an increased risk of injury due to the inability of damaged trailers to support the weight of the powered industrial truck used to load or unload the trailer. The goal of this lesson is create awareness of these hazards and to provide knowledge to the learner on how to avoid accidents and/or injury. -

Common hazards associated with pallet jack operation include falling objects (struck by hazards). Loads can fall, and operators can too. If you move a loaded pallet jack too quickly, over uneven floors, or on inclines, the load may topple. You could be injured if the load falls, and the load and/or the workplace may be damaged. Straining to move a stuck pallet jack or failing to maintain control on an incline can cause the operator to slip and fall. This lesson focuses on the safe operation of both manual and powered hydraulic pallet jacks.

Common hazards associated with pallet jack operation include falling objects (struck by hazards). Loads can fall, and operators can too. If you move a loaded pallet jack too quickly, over uneven floors, or on inclines, the load may topple. You could be injured if the load falls, and the load and/or the workplace may be damaged. Straining to move a stuck pallet jack or failing to maintain control on an incline can cause the operator to slip and fall. This lesson focuses on the safe operation of both manual and powered hydraulic pallet jacks. -

According to the National Federation of Independent Businesses defines ideal safety accountability as the following:

According to the National Federation of Independent Businesses defines ideal safety accountability as the following:- Ideal accountability

- Companies that strive for optimal safety performance display the highest level of organizational safety accountability

-

As simple as using a ladder seems to be, the injury statistics indicate that it is one of the most abused tools we have. Accidents, particularly in the domestic setting, are frequently caused by overreaching or overextending from ladders to complete certain tasks, rather than doing the safe thing—climbing down and moving to a better access point. OSHA studies have shown that 100% of ladder related accidents could have been prevented using proper safety. The goal of this lesson is to provide awareness-level instruction on ladder hazards, safe use requirements, and best practices for all employees.

As simple as using a ladder seems to be, the injury statistics indicate that it is one of the most abused tools we have. Accidents, particularly in the domestic setting, are frequently caused by overreaching or overextending from ladders to complete certain tasks, rather than doing the safe thing—climbing down and moving to a better access point. OSHA studies have shown that 100% of ladder related accidents could have been prevented using proper safety. The goal of this lesson is to provide awareness-level instruction on ladder hazards, safe use requirements, and best practices for all employees. -

This Lock and Tag lesson creates awareness about the purpose of lock and tag procedures and employee roles and responsibilities related to lock and tag requirements. The lesson provides an overview of the hazards of uncontrolled energy sources and employer responsibilities and requirements for lock and tag. It also briefly outlines steps to protect workers.

This Lock and Tag lesson creates awareness about the purpose of lock and tag procedures and employee roles and responsibilities related to lock and tag requirements. The lesson provides an overview of the hazards of uncontrolled energy sources and employer responsibilities and requirements for lock and tag. It also briefly outlines steps to protect workers. -

In this lesson, you will learn about the most-common vector-borne diseases and how you can avoid exposure and infection. You will learn general treatment guidelines; however, any treatment-related information provided in this lesson does not constitute medical advice and is not a substitute for evaluation by a qualified healthcare professional.

In this lesson, you will learn about the most-common vector-borne diseases and how you can avoid exposure and infection. You will learn general treatment guidelines; however, any treatment-related information provided in this lesson does not constitute medical advice and is not a substitute for evaluation by a qualified healthcare professional.